1390 Mashiinka goynta saxda ah ee sare

Bandhiga Alaabta

Halbeegga farsamada

| Goobta shaqada | 1300*900mm | Calaamadda Madaxa Laser | Raytools |

| Fiber laser power | Ikhtiyaar:1000W/1500w/2000w/3000W iwm. | Qaybaha xudunta u ah | Matoorka |

| Xawaaraha goynta ugu badan | 0-40m/daqiiqo | Tilmaam:

| Si buuxda u xidhan |

| Ku soo celi saxnaanta meelaynta | 0.02mm | Qaabka loo shaqeeyo | mowjad joogto ah |

| korontada | 220V/50Hz/60Hz | matoor iyo darawal | Japan YASKAWA servo motor & darawalka / dhimay Faransiiska |

| heerkulka deegaanka | 0-35°C | Qaab Sawireedka Waa La Taageeray | AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Waqti shaqo oo joogto ah | 24 saacadood | Aagga Goynta | 1300*900mm,1300*1300mm |

| Miisaanka mashiinka | 1500kg | Qodobbada Iibka Muhiimka ah | Saxnaanta sare |

| Nolosha dabiiciga ah ee laser | 100000 saacadood | Nidaamka gudbinta | gudbinta isku dhufashada kubbadda |

| Kontoroolka Software | Wareeg | MAX dardargelinta | 0.5G |

| Nidaamka qaboojinta | Biyo qaboojinta | Ku celi saxnaanta goobta:

| ± 0.006mm |

Dhumucda goynta

| Qalabka Goynta Laser-ka | ||||||||

|

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | 8000W | |

| Qalab | Dhumucda | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min |

| Birta kaarboon | 1 | 8--13 | 15--24 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 3.0--4.5 | 5--7.5 | 5.5--8 | 7--9 | 8--10 | 9--12 | 10--13 | |

| 3 | 1.8--3.0 | 2.4--4 | 3.5-4.8 | 4--6.5 | 4.5--6.5 | 4--7 | 4--7 | |

| 4 | 1.3-1.5 | 2--2.4 | 2.8-3.5 | 3.5--4.5 | 4.0--5.0 | 4.2--5.5 | 4.7--5.5 | |

| 5 | 0.9--1.1 | 1.8--2 | 2.5--3 | 3--3.5 | 3.0--4.2 | 3.5--4.2 | 3.8--4.5 | |

| 6 | 0.6--0.9 | 1.4--1.6 | 1.8--2.6 | 2.5--3.2 | 3.0--3.5 | 3.0--4 | 3.3--4.2 | |

| 8 |

| 0.8--1.2 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | 2.2--3.2 | 2.5--3.5 | |

| 10 |

| 0.6--1.0 | 1.1-1.3 | 1.4--2.0 | 1.5--2.5 | 1.8--2.5 | 2.2--2.7 | |

| 12 |

| 0.5--0.8 | 0.9--1.2 | 1.2--1.6 | 1.4--2 | 1.6--2 | 1.8--2.1 | |

| 14 |

|

| 0.7-0.8 | 0.9--1.4 | 1.0--1.6 | 1.5--1.8 | 1.7--1.9 | |

| 16 |

|

| 0.6-0.7 | 0.8--1.2 | 0.8--1.2 | 0.8--1.5 | 0.9--1.7 | |

| 18 |

|

| 0.4--0.6 | 0.7--1 | 0.8--1.1 | 0.9--1.2 | 0.9--1.2 | |

| 20 |

|

|

| 0.6--0.8 | 0.7--1 | 0.8--1.1 | 1.0--1.5 | |

| 22 |

|

|

| 0.4--0.6 | 0.6--0.8 | 0.7--0.9 | 0.8--1.0 | |

| 25 |

|

|

|

| 0.3--0.5 | 0.4--0.6 | 0.5--0.7 | |

| birta aan-dhalatada lahayn | 1 | 8--13 | 18--25 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 2.4--5.0 | 7--12 | 10--17 | 18--21 | 20--30 | 30--42 | 40--55 | |

| 3 | 0.6--0.8 | 1.8--2.5 | 4--6.5 | 8--12 | 12--18 | 18--24 | 30--38 | |

| 4 |

| 1.2--1.3 | 3--4.5 | 6--9 | 8--12 | 10--18 | 18--24 | |

| 5 |

| 0.6--0.7 | 1.8-2.5 | 3.0--5.0 | 4--6.5 | 8--12 | 12--17 | |

| 6 |

|

| 1.2-2.0 | 3.0--4.3 | 4.0--6.5 | 6--9 | 8--14 | |

| 8 |

|

| 0.7-1 | 1.5--2.0 | 1.8--3.0 | 4--5 | 6--8 | |

| 10 |

|

|

| 0.8--1 | 0.8--1.5 | 1.8--2.5 | 3--5 | |

| 12 |

|

|

| 0.5--0.8 | 0.6--1.0 | 1.2--1.8 | 1.8--3 | |

| 15 |

|

|

|

| 0.5--0.8 | 0.6--0.8 | 1.2--1.8 | |

| 20 |

|

|

|

| 0.4--0.5 | 0.5--0.8 | 0.6--0.7 | |

| 25 |

|

|

|

|

| 0.4--0.5 | 0.5--0.6 | |

| 30 |

|

|

|

|

|

| 0.4--0.5 | |

| Aluminium | 1 | 4--5.5 | 6--10 | 20--25 | 25--40 | 40--55 | 55--65 | 80--90 |

| 2 | 0.7--1.5 | 2.8--3.6 | 7--10 | 10--18 | 15--25 | 25--35 | 35--50 | |

| 3 |

| 0.7--1.5 | 4--6 | 7--10 | 10--15 | 13--18 | 21--30 | |

| 4 |

|

| 2--3 | 4--5.5 | 8--10 | 10--12 | 13--18 | |

| 5 |

|

| 1.2-1.8 | 3--4 | 5--7 | 6--10 | 9--12 | |

| 6 |

|

| 0.7--1 | 1.5--2.5 | 3.5--4 | 4--6 | 4.5--8 | |

| 8 |

|

|

| 0.7--1 | 1.5--2 | 2--3 | 4--6 | |

| 10 |

|

|

| 0.5--0.7 | 1--1.5 | 1.5--2.1 | 2.2--3 | |

| 12 |

|

|

|

| 0.7--0.9 | 0.8--1.4 | 1.5--2 | |

| 15 |

|

|

|

| 0.5--0.7 | 0.7--1 | 1--1.6 | |

| 20 |

|

|

|

|

| 0.5--0.7 | 0.7--1 | |

| 25 |

|

|

|

|

|

| 0.5--0.7 | |

| Naxaas | 1 | 4--5.5 | 6--10 | 14--16 | 25--35 | 35--45 | 50--60 | 70--85 |

| 2 | 0.5--1.0 | 2.8--3.6 | 4.5--6.5 | 10--15 | 10--15 | 25--30 | 30--40 | |

| 3 |

| 0.5--1.0 | 2.5--3.5 | 5--8 | 7--10 | 12--18 | 15--24 | |

| 4 |

|

| 1.5--2 | 3.5-5.0 | 5--8 | 8--10 | 9--15 | |

| 5 |

|

| 1.4-1.6 | 2.5--3.2 | 3.5-5.0 | 6--7 | 7--9 | |

| 6 |

|

|

| 1.2--2.0 | 1.5--2.5 | 3.5--4.5 | 4.5--6.5 | |

| 8 |

|

|

| 0.7-0.9 | 0.8--1.5 | 1.6--2.2 | 2.4--4 | |

| 10 |

|

|

|

| 0.5--0.8 | 0.8--1.4 | 1.5--2.2 | |

| 12 |

|

|

|

|

| 0.6--0.8 | 0.8--1.5 | |

| 16 |

|

|

|

|

|

| 0.6--0.8 | |

Qaybaha ugu muhiimsan

Codsiga

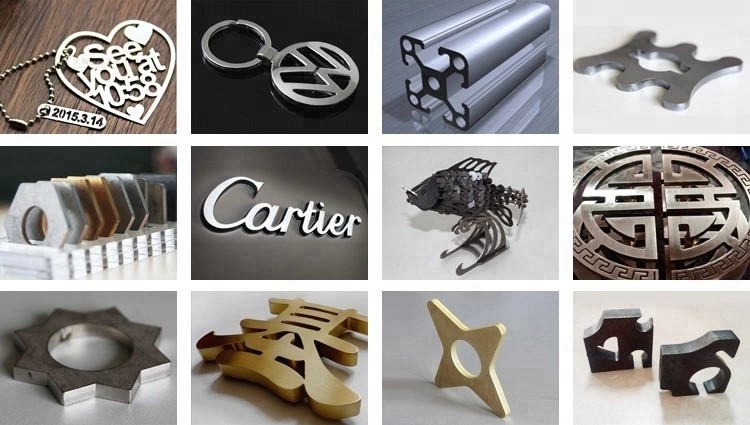

Warshadaha codsiga:

1390 High Precision Laser Cutting Machine waxaa si weyn loogu isticmaalaa soo saarista Billboard, Xayeysiiska, Calaamadaha, Calaamadaha, Waraaqaha Birta, Waraaqaha LED, Ware Jikada, Warqadaha Xayeysiiska, Qalabaynta Sheet Birta, Qaybaha Biraha iyo Qaybaha Qaabka, Qaybaha Elektarooniga ah, Taarikada Magaca, iwm. hubi in ay ku shaqayn karto ng suurtogal ah inta lagu jiro habka goynta laysarka.

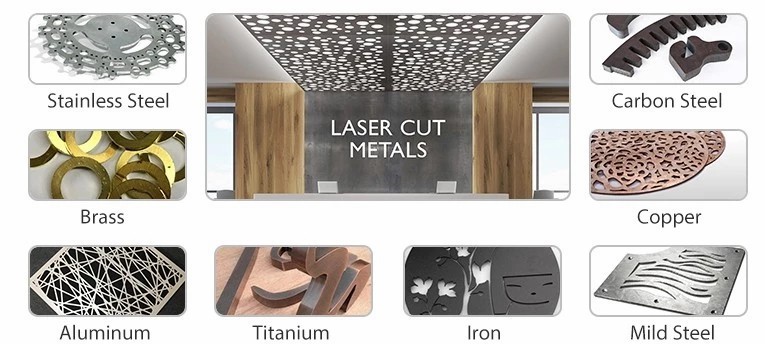

Qalabka Codsiga:

Xaashiyaha Biraha ah, Saxan Fudud, Xaashiyaha Birta Kaarboon, Xadhkaha Birta, Xadhkaha Birta, Birta Galvanized, Galvanized Sheet, Aluminium Plate, Sheet Copper, Sheet Naxaas ah, Saxan Naxaas ah, Saxan Dahab ah, Saxan Qalin, Plate Titanium, Sheet bir ah, Plate Plate, iwm

Tusaalooyinka

Faa'iidada

1. Goynta ganaax, ilaa 0.05-0.1mm. Isticmaal gaaska kaaliyaha ah ee ku habboon, adoo ka dhigaya jeexyada nadiif ah oo siman, uma baahna dhalaalid labaad.

2.Focusing madaxa goynta si toos ah.using of soo dejinta sare-horumarka capacitive shidma,-waqtiga-buuxa dynamic saxan height.Adjusting height goynta si toos ah in ay ka hortagto isku dhaca, waxaad gooyn kartaa saxan aan sinnayn.

3. Mashiinka goynta wuxuu qaataa wadista gawaarida servo ee dibedda laga keeno, soo dejinta moduleka toosan ee saxda ah, dhakhso badan, saxsan sare ilaa 0.01mm. Nolosha adeeg oo dheer.

4.Isticmaalka laser fiber-ka horumarsan, aaladaha asaasiga ah waa la soo dhoofiyaa. Degenaansho sare, nolol dheer, sahay la'aan, dayactir la'aan.

Naqshad 5.Professional ee qalabka dib u soo kabashada budada dahabka, boodhka iyo boodhka ayaa soo ururiyay dhammaan qalabka soo kabashada. Markaa khasaaraha ugu yaraan.

6.For dahab iyo qalin warshadaha dahabka dahabka xirfadeed nidaamka goynta laser caadadii, oo leh wanaajinta dariiqa, jarida kor u qaadista barta bilowga, lakabyo badan, shaqada qaabeynta, badbaadinta wakhtiga iyo alaabta.

7.Small size, isticmaalka tamarta yar, sahayda yar, dayactirka fudud. Hawo cadaadis leh ayaa sidoo kale la gooyn karaa, qiimo jaban.