Mashiinka Calaamadaynta Laser-ga Gacanta

Bandhiga Alaabta

Halbeegga farsamada

| Codsiga | Calaamadaynta Laser | Saxnaanta Shaqada | 0.01mm |

| Calaamada Isha Laser | Raycus/Jpt | Aagga Calaamadaynta | 110mm*110mm/200*200mm/300*300mm |

| Balaadhka Khadka Yar | 0.017mm | Miisaanka (Kg) | 65 Kg |

| Dabeecada ugu yar | 0.15mm | Calaamadaynta Qoto dheer | 0.01-1.0mm (Mawduuca Agabka) |

| Qaab Sawireedka Waa La Taageeray | Ai, Plt, Dxf, Bmp, Dst, Dwg, Dxp | Warshadaha lagu dabaqi karo | Hoteelada, Dukaamada Dharka, Dukaamada Qalabka Dhismaha |

| Mawjada dhererka | 1064nm | Adeegga Iibka Kadib La Bixiyay | Taageerada Farsamada Fiidiyowga, Taageerada khadka, Qaybaha Hadhaaga |

| Qaabka Hawlgalka | Buug ama Toos ah | Saxnaanta Shaqada | 0.001mm |

| Xawaaraha calaamadaynta | ≤7000mm/s | Nidaamka qaboojinta | Qaboojinta hawada |

| Nidaamka Xakamaynta | Jcz | Software | Ezcad Software |

| Qaabka Hawlgalka | garaacid | Muuqaal | Dayactirka hooseeya |

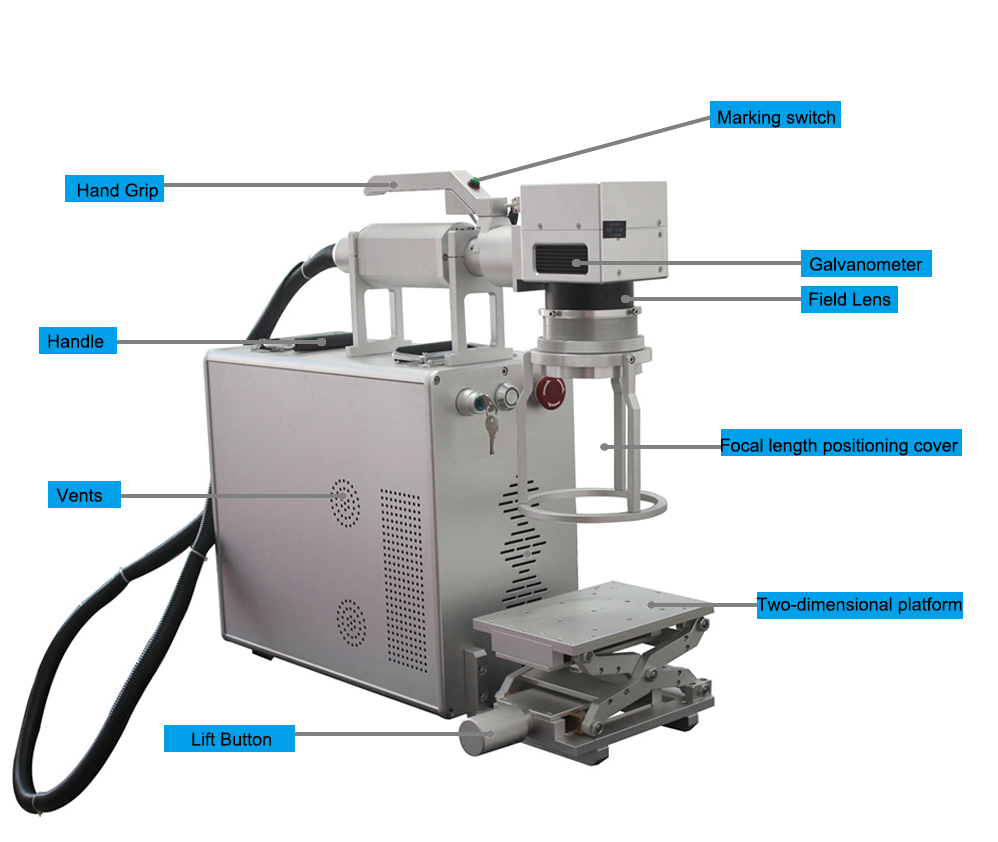

| Habaynta | Nooca Gacanta lagu hayo | Habka meelaynta | Meelaynta Iftiinka Cas ee Laba-laaban |

| Kormeerka Bixinta Fiidiyowga | Bixiyay | Qaab Sawireedka Waa La Taageeray | Ai, Plt, Dxf, Dwg, Dxp |

| Meesha Asal ahaan | Jinan, Gobolka Shandong | Waqtiga Damaanada | 3 Sano |

Faa'iidada mashiinka calaamadaynta laser fiber

1.Compact Naqshad: Alaabada tignoolajiyada sare leh, oo ay kujiraan qalabka leysarka, kumbuyuutarka, xakameynta auto iyo mashiinada saxda ah. Waa naqshad yar oo dhamaystiran.

2.Saamaynta saxnaanta sare ee saxda ah: ku habboon calaamadaynta saxda ah ee qaybaha birta, qaybaha elektaroonigga ah iwm.

Xawaaraha Calaamadaynta Sare: Nidaamka iskaanka waxa uu ka dhigayaa fibre calamaynta mishiinka xawaarihiisa ilaa 7000-12000mm/s.

3.Long Service Time: Fiber laser marking Machine wuxuu qaataa tiknoolajiyada caalamiga ah ee ugu horumarsan iyo isha laserku waa fiber oo leh tignoolajiyada sare ee aduunka, noloshu waxay gaari kartaa saacadaha 100,000, 8-10 sano iyada oo aan la isticmaalin iyo dayactir.

4.Small size iyo dhaqdhaqaaqa fudud;

Hawlgalka 5.Easy: looma baahna hagaajin jidka laysarka, waxaad calaamadin kartaa calaamadaha, lambarada, sawirada iwm, si toos ah u .Afford software calaamad gaar ah oo ku salaysan Windows, taas oo ah wakhtiga dhabta ah hagaajinta awoodda calaamadaynta laser fiber iyo garaaca garaaca wadnaha. Waxaad ku qori kartaa oo ku soo saari kartaa kombuyuutar iyadoo loo eegayo tafatirka labadaba software-ka calaamadaynta gaarka ah iyo softiweerka garaafyada sida AutoCAD, CorelDRAW ama Photoshop.

6. Saamaynta calaamadaynta joogtada ah.

7.Qiimaha orodka hooseeya: Qayb xidhid la'aan. Ilaalinta bilaashka ah.

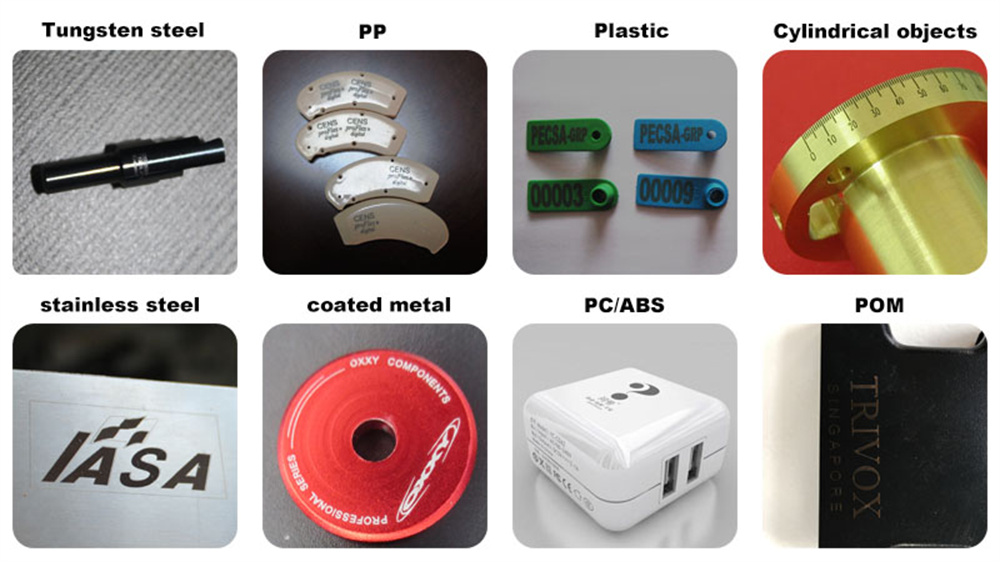

Qalabka lagu dabaqi karo iyo muunadaha calaamadaynta

1.Metals: dahab, qalin, titanium, copper, daawaha, aluminium, birta, birta manganese, magnesium, zinc, birta ah, carbon steel / birta khafiif ah, dhammaan noocyada kala duwan ee birta daawaha, saxan electrolytic, saxan naxaas ah, xaashi galvanized , Aluminium, dhammaan noocyada kala duwan ee taarikada alloy, dhammaan noocyada kala duwan ee biraha xaashida, biraha dhif ah, aluminium dahaarka leh ee dusha sare ee gaarka ah, biraha dahaarka leh ee electroplated ah, aluminium-magnesium alloy dusha oksijiinta burbursa.

2. Non-bireed: Qalabka daahan aan biraha ahayn, balaastikada warshadaha, caag adag, caag, ceramics, resins, plexiglass, resin epoxy, resin acrylic, qalab polyester unsaturated.

Warshadaha lagu dabaqi karo:

Furaha telefoonka gacanta, furayaasha translucent caag ah, qaybaha elektarooniga ah, isku dhafan wareegyada (IC), qalabka korontada, alaabta isgaarsiinta, alaabta nadaafadda, qalabka, qalabyada, mindiyo, muraayadaha indhaha iyo saacadaha, dahabka, qaybaha baabuurta, xidhitaan shandadaha, maacuunta wax lagu kariyo, alaabta birta ahama iyo warshado kale.

Xidhmada iyo gaadiidka