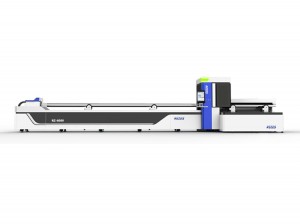

Mashiinka Goynta Mashiinka Laydhka ee Laba-laaban ee Platform

Bandhiga Alaabta

Halbeegga farsamada

| Codsiga | Goynta Laser-ka | Qalabka lagu dabaqi karo | Birta |

| Aagga Goynta | 1500mm*3000mm | Nooca Laser | Fiber Laser |

| Kontoroolka Software | Wareeg | Calaamadda Madaxa Laser | Raytools |

| chuck penumatic | 20-350mm | Dhererka Chuck | 3m/6m |

| Magaca Servo Motor | Yaskawa motor | Warbixinta Tijaabada Mashiinada | Bixiyay |

| Qaab Sawireedka Waa La Taageeray | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC ama maya | Haa |

| Qodobbada Iibka Muhiimka ah | Saxnaanta sare | Dammaanadda qaybaha asaasiga ah | 12 bilood |

| Qaabka loo shaqeeyo | si toos ah | Meelaynta Saxnaanta | ±0.05mm |

| saxnaanta dib-u-dhigista | ±0.03mm | Dardargelinta ugu sarreysa | 1.8G |

| Warshadaha lagu dabaqi karo | Hudheelada, Dukaamada Qalabka Dhismaha, Warshada wax soo saarka | Qaybaha sambabada | SMC |

| Qaabka loo shaqeeyo | mowjad joogto ah | Muuqaal | madal labanlaab ah |

| Xawaaraha Goynta | ku xiran tahay awoodda iyo dhumucda | Kontoroolka Software | Tubepro |

| Dhumucda Goynta | 0-50mm | Calaamada Hagaha | HIWIN |

| Qaybaha korantada | schneider | Waqtiga dammaanadda | 3 sano |

Dayactirka Mashiinka

1.Cooling nidaamka dayactirka

Biyaha ku jira qaboojiyaha biyaha waxay u baahan yihiin in si joogto ah loo beddelo, inta jeer ee beddelkuna waa hal bil.Mashiinka qaboojinta biyaha ayaa mas'uul ka ah qaboojinta laysarka iyo qaybaha kale ee qalabka sida wareegga biyaha.Way fududahay in la sameeyo miisaan marka tayada biyaha la isticmaalo wakhti dheer, taas oo xannibaysa marin biyoodka oo keenaya in socodka biyuhu hoos u dhaco oo uu yareeyo saamaynta qaboojinta.Sidaa darteed, beddelka biyaha joogtada ah waa dhibaatada koowaad.Biyaha waa in la nadiifiyaa intii suurtagal ah.Haddii aysan jirin xaalad, biyaha deionized waa la dooran karaa.Soo-saare kastaa wuxuu leeyahay shuruudaha tayada biyaha, waana muhiim in la buuxiyo shuruudaha.Haddii kale, isticmaalka tayada biyaha ee aan u qalmin wakhti dheer waxay keeni doontaa khariidad gudaha ah ee laysarka.

2. dayactirka nidaamka ka saarista siigada

Isticmaalka marawaxadu muddada dheer waxa ay keenaysaa in boodh adag ay ku ururto gudaha marawaxada,taasi oo dhalin doonta buuq badan oo aan ku haboonayn daalka iyo carfiska.Marka la waayo nuugista marawaxada, waxa marka hore la daminayaa korontada, waxa la saarayaa tuubada hawada soo gelisa iyo tuubada hawada ka soo baxda marawaxada, waxa la saarayaa siigada gudaha ku jirta, ka dibna marawaxada ayaa rogan, oo marawaxada kor loo qaado ilaa ay nadiif noqoto.Kadibna ku rakib marawaxada.

3. Dayactirka nidaamka indhaha

Laysarku waxa uu ka muuqdaa muraayadda oo waxa uu diiradda saarayaa madaxa laysarka.Ka dib marka uu qalabku socdo muddo wakhti ah, dusha sare ee muraayadda ayaa lagu dabooli doonaa boodh, taas oo si weyn u saameyn doonta muraayadda muraayadda iyo gudbinta muraayadda, taas oo keeneysa hoos u dhaca awoodda laser-ka.BoodhkaSi kastaba ha ahaatee, taxaddar markaad nadiifinayso.Lensku waa shay jilicsan.Waa inaad ku isticmaashaa shay fudud ama shay adag si aad u taabato muraayada.

Tillaabooyinka nadiifinta muraayadda iyo taxaddarrada waa sida soo socota: Marka hore, isticmaal suuf suuf ah iyo ethanol si aad si taxadar leh ugu tirtirto bartamaha muraayadda ilaa cidhifka.Muraayada ayaa u baahan in si tartiib ah loo tirtiro.Dahaarka dusha sare waa in aan la dhaawacmin.Inta lagu jiro habka tirtiridda, si tartiib ah u qabooji si aad uga ilaaliso inuu soo dhaco.Marka aad rakibayso muraayadda diiradda saaraya, hubi in aad ka ilaaliso dhinaca koodhka oo hoos u jeeda.Intaa waxaa dheer, tirada daloolada xawaaraha sare ee aadka u sarreeya ayaa badanaa la yareeyaa inta suurtogalka ah, iyo isticmaalka daloolada caadiga ah waxay kordhin kartaa nolosha muraayadda diiradda.

4. Ilaalinta nidaamka gudbinta

Mashiinka goynta laysarka, habka gudbinta ayaa u dhigma cidhibta iyo cagaha qofka.Nidaamka gudbintu wuxuu si toos ah u saameeyaa hawlgalka caadiga ah iyo nolosha adeegga qalabka.Mashiinka goynta laser wuxuu dhalin doonaa qiiq inta lagu jiro habka goynta muddada-dheer.Boodhka wanaagsani wuxuu ka geli doonaa qalabka iyada oo loo marayo daboolka boodhka wuxuuna ku dhejin doonaa rafka tareenka.Ururinta muddada-dheer waxay kordhin doontaa ilkaha tareenada hagaha.Xirashada xariijinta, hagaha rack asal ahaan waa qalab aad u casrisan, wakhtiga dheerna wuxuu dhaawac u geysan doonaa jiidhiyaha iyo qalabka.Sidaa darteed, rafka tareenka waa in si joogto ah loo nadiifiyaa iyadoo boodhka laga saarayo.Ka dib marka la nadiifiyo boodhka ku xiran raafka, shalefku waa la subkay, tareenadana waxaa lagu saliimayaa saliid.

Video Machine

Mashiinka Goynta Sheet Birta & Tuubbada Fiber Laser-ka