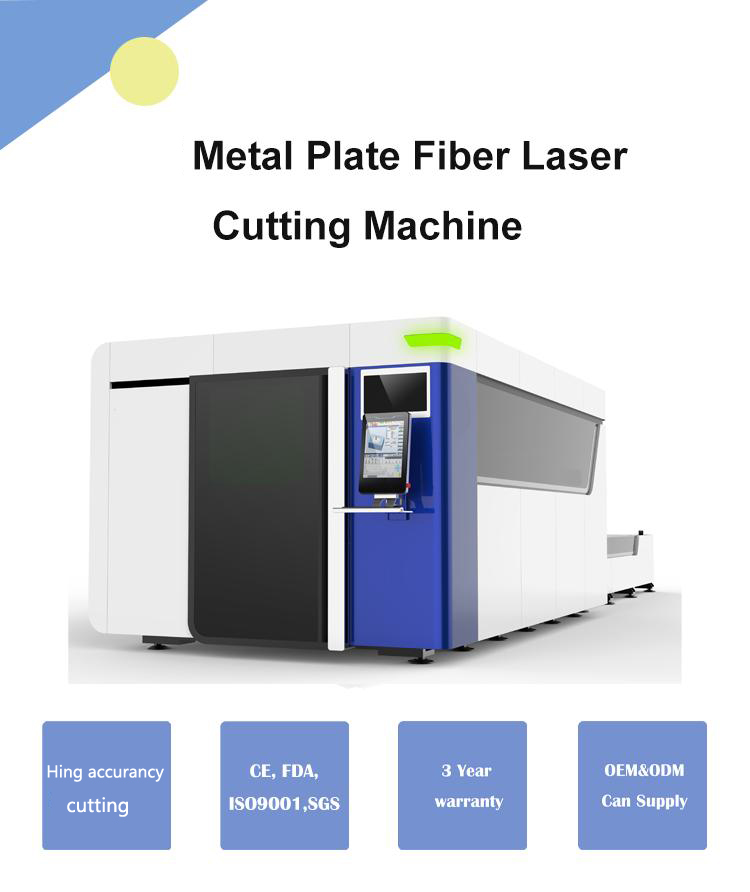

Mashiinka Goynta Laser Cover oo dhan

Bandhiga Alaabta

Halbeegga farsamada

| Codsiga | Goynta Laser-ka | Qalabka lagu dabaqi karo | Birta |

| Aagga Goynta | 1500mm*3000mm | Nooca Laser | Fiber Laser |

| Kontoroolka Software | Wareeg | Calaamadda Madaxa Laser | Raytools |

| Magaca Servo Motor | Yaskawa motor | Warbixinta Tijaabada Mashiinada | Bixiyay |

| Qaab Sawireedka Waa La Taageeray | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC ama maya | Haa |

| Qodobbada Iibka Muhiimka ah | Saxnaanta sare | Miisaanka | 4500kg |

| Qaabka loo shaqeeyo | si toos ah | Meelaynta Saxnaanta | ±0.05mm |

| saxnaanta dib-u-dhigista | ±0.03mm | Dardargelinta ugu sarreysa | 1.8G |

| Warshadaha lagu dabaqi karo | Hudheelada, Dukaamada Qalabka Dhismaha, Warshada wax soo saarka | Qaybaha sambabada | SMC |

| Qaabka loo shaqeeyo | mowjad joogto ah | Muuqaal | Dabool buuxa |

| Xawaaraha Goynta | ku xiran tahay awoodda iyo dhumucda | Kontoroolka Software | Tubepro |

| Dhumucda Goynta | 0-50mm | Calaamada Hagaha | HIWIN |

| Qaybaha korantada | schneider | Waqtiga dammaanadda | 3 sano |

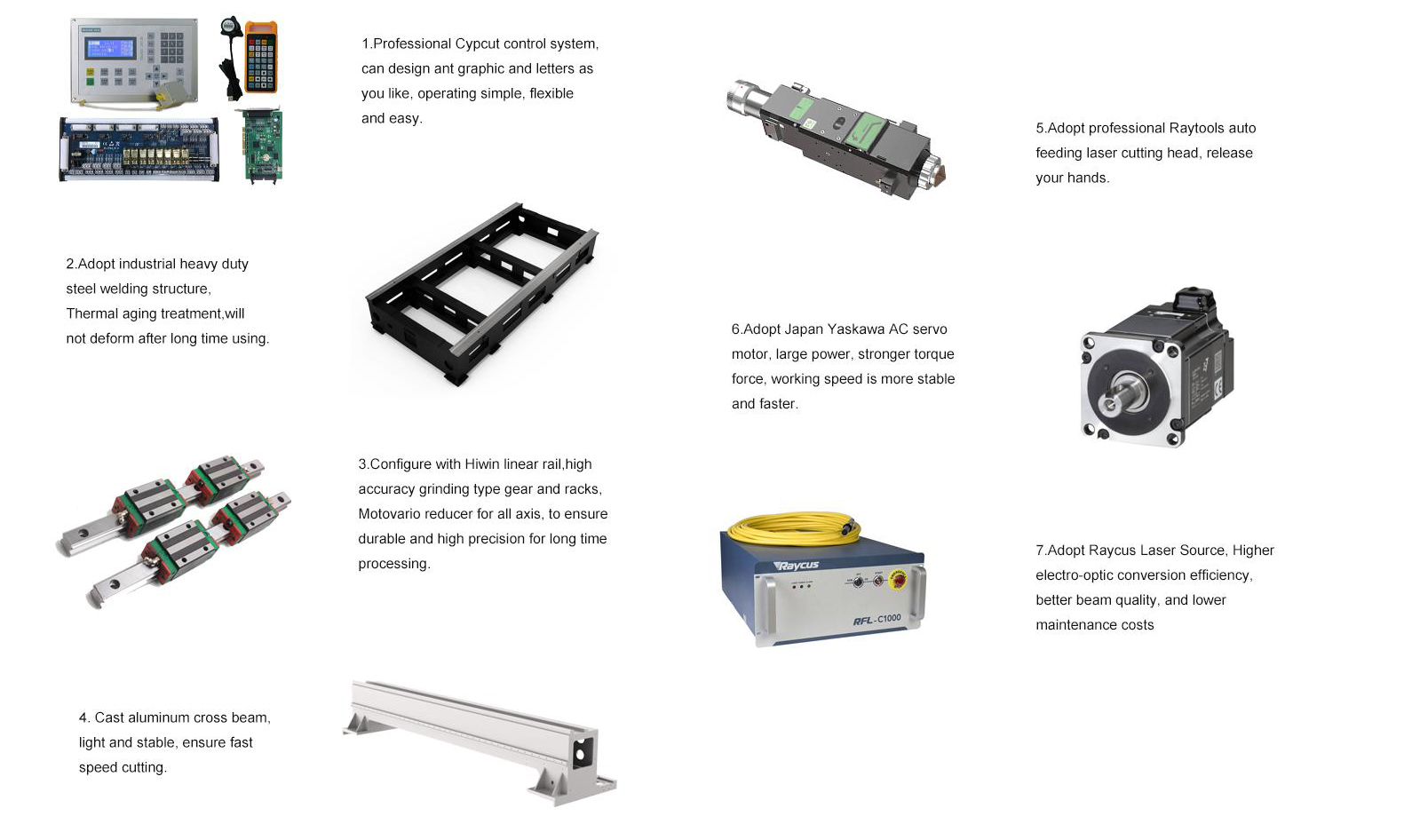

Qaybaha mashiinka

Video Machine

Mashiinka Goynta Laser Cover oo dhan

Tijaabooyin goyn

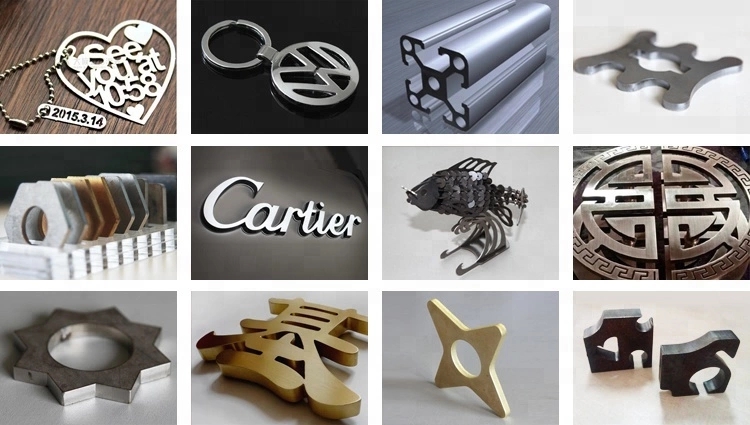

Codsiga

1. Warshadaha baabuurta

Mashiinnada goynta laser-ka waxaa loo isticmaalaa daboolka hore ee baabuurka, biraha baabuurka, tuubooyinka qiiqa baabuurta, iwm. Haddii hawlgalka gacanta la isticmaalo, way adag tahay in la gaadho heerka la doonayo ee hufnaanta iyo saxnaanta.

2. Warshadaha qurxinta

Warshadaha qurxinta waxay u baahan yihiin inay isticmaalaan sawiro badan oo adag, iyo mishiinka goynta laser-ka ayaa la kulmi kara codsiga warshadahan oo leh xawaaraha goynta degdega ah iyo goynta dabacsan, waana mid aad caan u ah shirkadaha qurxinta. Ka dib marka la naqshadeeyo sawirada ku habboon, soo dejinta hal-guji waa la gooyn karaa.

3. Warshadaha xayaysiinta

Mashiinnada Goynta Fiber Laser waxaa si weyn loogu isticmaalaa soo saarista Billboard-ka, Xayeysiinta, Calaamadaha, Calaamadaha, Xarfaha birta, Xarfaha LED-ka.

4.Alaabada guriga iyo warshadaha alaabta jikada

Qalabka guriga iyo maacuunta jikada asal ahaan waxay ka samaysan yihiin taarikada khafiifka ah. Kahor habka shaabadda iyo sawirka, mishiinka goynta laysarka fiber-ka waxaa loo isticmaalaa in lagu farsameeyo shaybaarada si dhakhso ah loo horumariyo alaabada cusub. Xawaaraha goynta ee qalabka farsamaynta laysarka waa mid degdeg ah, taas oo si weyn u wanaajisa hufnaanta processing. Isla mar ahaantaana, qalabka farsamaynta laysarka wuxuu leeyahay saxsanaan sare oo goyn ah, kaas oo wanaajinaya dhalidda daboolka kala duwan iyo qalabka gubanaya. Qaar ka mid ah alaabooyinka gaarka ah, mashiinnada goynta laysarka fiber-ka ayaa leh faa'iidooyin gaar ah, oo ay ku jiraan armaajooyinka qaybinta awoodda, armaajooyinka xereynta, iwm, kuwaas oo dhammaantood ah wax soo saar heer sare ah oo saxan khafiif ah waxayna u baahan yihiin hufnaan. Isticmaalka mashiinnada goynta laysarka ayaa si weyn u wanaajin kara waxtarka.

5. Warshadaha mishiinada beeraha

Waxaa jira noocyo badan oo ka mid ah qaybaha farsamaynta biraha xaashida ah ee alaabta mishiinada beeraha, si degdeg ahna waa loo cusboonaysiiyaa. Qaybaha farsamaynta biraha dhaqameed ee alaabta mishiinada beeraha waxay inta badan isticmaalaan habka feerka, kaas oo cuna caaryada badan. Haddii farsamaynta qaybaha ay weli ku sii jirto habka dhaqameed, waxay si dhab ah u xaddidi doontaa beddelka alaabta. Tilmaamaha farsamaynta dabacsan ee laysarka ayaa ka muuqda. Ka-hortagga Laserku wuxuu ogaan karaa goynta qaababka kala duwan ee taarikada iyadoo la kaashanayo barnaamijyada barnaamijyada. Isticmaalka habka laser ma aha oo kaliya inuu leeyahay xawaaraha processing degdeg ah, hufnaan sare, iyo qiimo jaban, laakiin sidoo kale uma baahna in la beddelo caaryada ama qalabka, gaabinaya wakhtiga diyaarinta wax soo saarka. Waxa kale oo ay la socon kartaa xawaaraha marka alaabta la cusboonaysiiyo, qaabka cusubna waxa lagu gooyn karaa dib-u-samaynta iyo barnaamijka. Way fududahay in la ogaado processing joogto ah, wakhtiga transposition beam laser waa gaaban yahay, iyo waxtarka wax soo saarka waa sare. Qaybo shaqo oo kala duwan ayaa lagu rakibi karaa si kale. Marka workpiece la farsameeyo, qaybaha la dhammeeyey waa laga saari karaa iyo workpiece in la farsameeyo lagu rakibo karaa si ay u ogaadaan processing barbar socda.

6. Warshadaha dhismaha

In warshadaha mashiinada dhismaha, fiber laser goyn godadka wareeg ah loo isticmaali karaa ilaa inta dhexroorka godka workpiece ka weyn yahay ama la siman dhumucda saxan, iyo qallafsanaanta iyo shuruudaha dhexroor yihiin gudahood awoodda damaanad qaadka mashiinka goynta marka ay la kulmaan dhumucdiisuna saxan gaar ah. Laserku wuxuu si toos ah u gooyaa walxaha, baabi'inta habka qodista iyo hagaajinta waxtarka wax soo saarka shaqada. Qaar ka mid ah workpieces oo leh godad badan, shaqada dhibco ee mashiinka goynta laser fiber waxaa loo isticmaalaa si loo go'aamiyo booska godka, kaas oo badbaadiya waqtiga meelaynta godka ee habka qodida godka xiga, iyo sidoo kale badbaadiyo kharashka wax soo saarka ee template qodista, taas oo aan hagaajinaysaa oo kaliya waxtarka wax soo saarka, laakiin sidoo kale hagaajinaysaa saxnaanta alaabta.